Digital Transformation: Manufacturing

Optimizing factory production through digital twins, AI-powered predictive maintenance, and interconnected industrial IoT ecosystems.

Happy Wednesday!

Insight Trunk is a free lifetime library—a modern replacement for outdated encyclopedias. From Monday to Saturday, we deliver a 10-minute read on a specific subject, with fresh topics each week. Two years later, we revisit each theme with updated insights from our archives—so you’ll never miss a thing. You can unsubscribe anytime using the link at the bottom of this newsletter.

Today, we step onto the factory floor of the future: Industry 4.0. We will explore how Digital Twins simulate production lines to perfection and how predictive maintenance eliminates costly downtime. We also uncover the power of Industrial IoT and modern ERP systems in unifying manufacturing operations.

🧑💻 In this week’s edition: Digital Transformation

Monday - Banking and Finance

Tuesday - Logistics and Supply Chain

Wednesday - Manufacturing

Thursday - Healthcare

Friday - Government

Saturday - Agriculture

Question of the day

What technology allows manufacturers to test changes on a virtual replica before applying them physically?

Let’s find out !

Manufacturing

Let’s break it down in today discussion:

Digital Twin Technology: The Virtual Mirror of Production

Predictive Maintenance: Eliminating Unplanned Downtime

The Industrial Internet of Things (IIoT): The Connected Ecosystem

Integrated ERP Systems: The Strategic Command Center

Read Time : 10 minutes

♊ Digital Twin Technology: The Virtual Mirror of Production

In the vanguard of Industry 4.0, Digital Twin technology represents a fundamental paradigm shift from static design to dynamic, real-time simulation. A digital twin is not merely a static 3D model; it is a living virtual entity that mirrors a physical asset, process, or system with high-fidelity precision. By integrating continuous data streams from Internet of Things (IoT) sensors embedded in factory machinery, the digital counterpart evolves simultaneously with its physical twin, reflecting its current status, performance metrics, and wear levels in real-time.

This synchronization empowers manufacturers to conduct rigorous stress testing and scenario analysis in a risk-free virtual environment. Engineers can simulate complex production changes—such as reconfiguring an assembly line for a new product variant—to identify potential bottlenecks or collisions before any physical equipment is moved. For instance, in the automotive sector, manufacturers utilize digital twins to model the aerodynamic performance of a vehicle prototype under thousands of virtual weather conditions, significantly reducing the reliance on costly physical wind tunnel testing.

Consequently, this technology serves as a critical tool for predictive optimization and risk mitigation. By validating operational adjustments digitally, organizations can ensure immediate efficiency upon physical implementation, dramatically shortening time-to-market. The ability to “fail fast” in the virtual realm prevents expensive disruptions on the factory floor, ensuring that the physical production line operates with maximum uptime and efficiency.

Want to go beyond the basics? This video is a great resource.

📉 Predictive Maintenance: Eliminating Unplanned Downtime

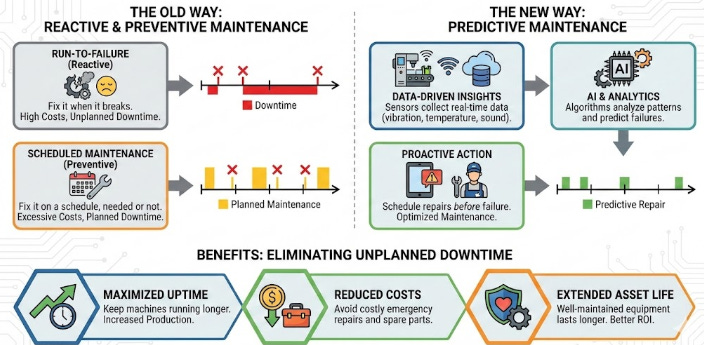

Historically, industrial maintenance has relied on inefficient methodologies: either reactive (repairing equipment after failure) or preventive (replacing parts on a fixed schedule, regardless of actual wear). Predictive maintenance (PdM) revolutionizes this approach by leveraging artificial intelligence and machine learning to monitor asset health in real-time. By analyzing continuous data streams from sensors measuring vibration, temperature, and acoustic signatures, PdM algorithms can identify microscopic anomalies that precede a catastrophic failure.

Consider a critical turbine in a power plant. A predictive maintenance system might detect a slight increase in vibration frequency coupled with a minor temperature rise—deviations too subtle for a human operator to notice. The AI correlates these signals to predict a specific bearing failure within the next 200 operational hours. This insight allows the maintenance team to schedule repairs during a planned production lull, rather than suffering a sudden breakdown that halts the entire facility.

The financial and operational implications of this shift are profound. By transitioning from a “fail-and-fix” model to a “predict-and-prevent” strategy, manufacturers can reduce maintenance costs by up to 30% and eliminate up to 70% of unplanned downtime. This ensures that expensive capital assets are utilized to their maximum lifespan while maintaining consistent production throughput and safety standards.

For an in-depth look, make sure to watch this video.

📶 The Industrial Internet of Things (IIoT): The Connected Ecosystem

The Industrial Internet of Things (IIoT) serves as the digital nervous system of the smart factory, fundamentally transforming isolated machinery into a cohesive, intelligent network. Unlike traditional automation, where equipment operates in functional silos, IIoT embeds internet-enabled sensors and actuators into every facet of the production environment. This convergence of Operational Technology (OT) and Information Technology (IT) facilitates the continuous extraction of high-fidelity telemetry data, creating a unified infrastructure where the physical state of the factory is instantly visible to digital management systems.

A defining capability of this ecosystem is Machine-to-Machine (M2M) communication, which enables autonomous coordination between devices. For instance, in an automated bottling line, if a downstream labeling machine encounters a micro-stop or error, it can immediately transmit a signal to the upstream filling station to pause or decelerate. This lateral communication creates a self-regulating production flow that prevents inventory pile-ups and mechanical jams without requiring human intervention, thereby maintaining optimal line balancing.

Furthermore, the aggregation of this granular data unlocks deep insights into Overall Equipment Effectiveness (OEE). By analyzing real-time performance metrics across the entire shop floor, plant managers can identify hidden inefficiencies, monitor energy consumption patterns, and optimize throughput. This shifts manufacturing management from reactive firefighting to proactive, data-driven orchestration of the entire value chain.

Broaden your understanding by watching this video.

🧠 Integrated ERP Systems: The Strategic Command Center

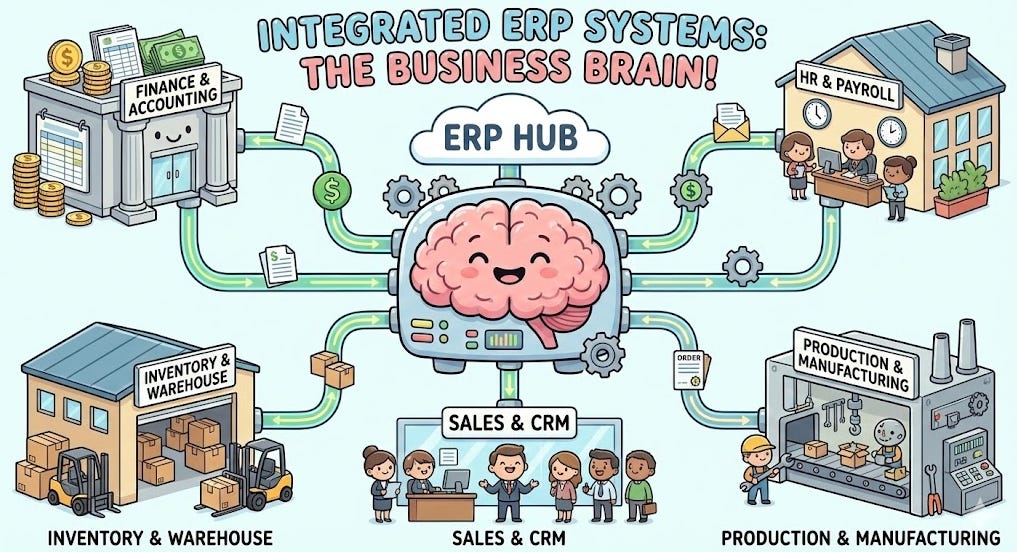

While the Industrial Internet of Things (IIoT) manages the immediate granularities of the factory floor, Enterprise Resource Planning (ERP) systems function as the overarching strategic brain of the manufacturing enterprise. In the Industry 4.0 landscape, modern cloud-based ERP solutions transcend traditional back-office record-keeping to become dynamic integrators. They bridge the gap between operational technology (OT) on the production line and information technology (IT) in the boardroom, dismantling data silos to create a unified, real-time view of the entire business ecosystem.

The true power of this integration is best demonstrated through the automated order-to-cash cycle. Consider a scenario where a customer submits a large volume order; an integrated ERP system instantly verifies finished goods inventory. If stock is insufficient, the system automatically triggers procurement orders for the specific raw materials required and reserves time slots on the production schedule. This synchronization ensures that manufacturing activity is strictly demand-driven, preventing both the financial drain of excess inventory and the reputational risk of missed delivery deadlines.

Furthermore, these systems provide financial clarity by calculating the precise cost of goods sold (COGS) in real-time. By capturing data on energy usage, labor hours, and material waste directly from machine sensors, the ERP enables management to identify unprofitable product lines or inefficient processes immediately. This holistic visibility allows for data-backed decision-making that aligns production capabilities with broader business objectives and market demands.

Ready to learn more? Dive into this video.

Summary

Digital Twin Technology

Virtual Mirroring: A digital twin is a dynamic, living replica of a physical asset or system that evolves in real-time using data streams from embedded IoT sensors.

Risk-Free Simulation: Manufacturers can use these virtual models to stress-test designs and simulate complex production changes without disrupting the actual factory floor.

Predictive Optimization: Engineers can validate operational adjustments digitally first (”fail fast”), ensuring that physical implementation is efficient immediately upon launch.

Reduced Time-to-Market: By perfecting processes in the virtual realm before physical commissioning, companies dramatically shorten the development cycle.

Deep Analytics: The technology allows for advanced scenario analysis, such as testing how a vehicle prototype handles thousands of weather conditions without needing a wind tunnel.

Predictive Maintenance (PdM)

Beyond Fixed Schedules: PdM moves away from reactive repairs or unnecessary preventive replacement, focusing instead on the actual health of the machine.

AI-Driven Detection: Algorithms analyze continuous sensor data (vibration, temperature, acoustics) to detect microscopic anomalies that human operators would miss.

Preventing Catastrophe: The system identifies failure patterns weeks in advance, allowing maintenance to be scheduled during planned lulls rather than causing emergency shutdowns.

Cost Efficiency: Implementing PdM can reduce maintenance costs by up to 30% by ensuring parts are only replaced when they are truly about to fail.

Asset Maximization: This strategy extends the useful lifespan of expensive capital equipment while ensuring consistent safety and production throughput.

Industrial Internet of Things (IIoT)

The Digital Nervous System: IIoT connects isolated machinery into a cohesive network, bridging the gap between Operational Technology (OT) and Information Technology (IT).

Machine-to-Machine (M2M) Communication: Devices can “talk” to one another autonomously; for example, a downstream machine can signal an upstream robot to slow down to prevent a jam.

Self-Regulating Flows: This lateral communication creates a production line that adapts automatically to micro-stops or errors without requiring human intervention.

Holistic Visibility: Aggregating granular sensor data provides managers with deep insights into Overall Equipment Effectiveness (OEE) and energy consumption.

Proactive Management: IIoT shifts factory management from reactive firefighting to a data-driven orchestration of the entire value chain.

Integrated ERP Systems

Strategic Command Center: Modern cloud ERPs act as the “brain,” integrating real-time production data with broader business functions like finance, sales, and procurement.

Demand-Driven Logic: The system automates the order-to-cash cycle; a sales order instantly triggers material checks and production scheduling, preventing overproduction.

Inventory Optimization: By synchronizing procurement with actual demand, companies avoid the financial drain of excess stock and the risk of stockouts.

Real-Time Financials: ERPs calculate precise Cost of Goods Sold (COGS) by capturing live data on energy and labor, helping identify unprofitable product lines immediately.

Dismantling Silos: The integration ensures that every department, from the shop floor to the boardroom, operates using a single, unified source of truth.

Five essential metrics for smart factories.

Overall Equipment Effectiveness (OEE): This “gold standard” metric combines availability, performance, and quality scores to show exactly how productive your manufacturing equipment actually is.

Cycle Time: This measures the total time required to produce a single unit from start to finish, identifying specific bottlenecks in the production line.

Throughput: This tracks the actual volume of units produced over a specific period, providing a clear picture of your factory’s real output capability.

Capacity Utilization: This reveals the percentage of your total potential production output that is currently being used, indicating whether you need to scale up or down.

First Pass Yield (FPY): This quality metric calculates the percentage of products that are manufactured correctly the first time without needing any rework or scrap.

Answer of the day

What technology allows manufacturers to test changes on a virtual replica before applying them physically?

Digital Twin technology.

Digital Twins are virtual models that mirror physical machines in real-time. By simulating production scenarios on these digital counterparts, manufacturers can identify bottlenecks and test process changes safely. This prevents costly physical errors and allows for optimization without ever stopping the actual assembly line.

That’s A Wrap!

Want to take a break? You can unsubscribe anytime by clicking “unsubscribe” at the bottom of your email.